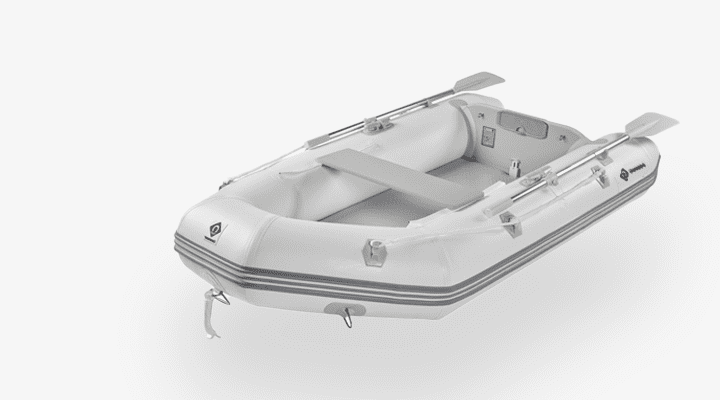

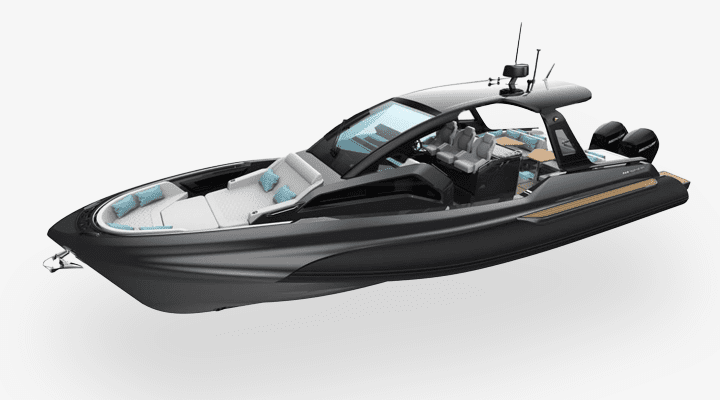

ZAR Formenti’s inception platform was built upon the principal “il coraggio di distinguire” – the courage to be distinguished.

As a result, in all facets of design, research, technology, fabrication and cruising experience they have achieved a unique place in the inflatable, RIB Tender and Sport boat markets. Designed with superior qualities of safety, sea-worthiness, flexibility and comfort, ZAR boats assure a remarkable passenger experience.

The lengthened hulls combined with reduced tube length and lateral reverse tunnels are unique. They create an unparalleled, smooth, pitch-less cruise that can only be compared to boats of a much longer length. These vessels are meticulously manufactured with the intents of safety and practicality.

There is a clear dedication to these details; grab-handles for all passengers,

- no projections that could cause injuries,

- water-tight seals,

- vent wings on the windscreen,

- seals under metal parts,

- self- locking screws and nuts.

No design or construction aspect has gone unconsidered. Passengers enjoy ergonomic seats, modular lay-out of spaces and the cruise of a vessel that clearly belongs powering a course on the water.

Designed with superior qualities of safety, sea-worthiness, flexibility and comfort, ZAR Rigid Hull Inflatable Boats (RHIB) assure a remarkable passenger experience.

HULL CONCEPTION & FABRICATION

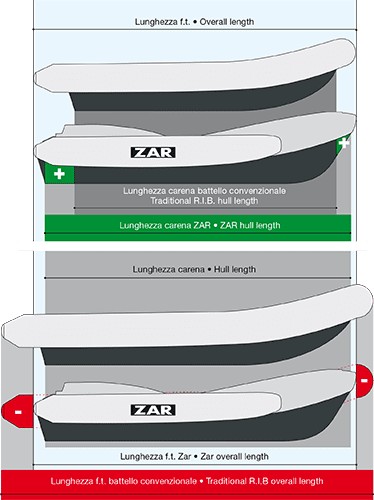

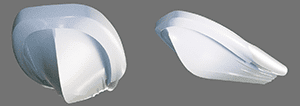

Of all facets of the design, hull size is the most important in the navigation quality of a R.I.B. (Rigid Inflatable Boat). Because of the forward tubular absence and the transom moved backwards, all the ZAR models are equipped with a quite longer hull than all the other traditional R.I.B. of the same overall length. The absence of the tubular element in the bow (internationally patented) has enabled Formenti ZARs to be built with a very deep V. The lateral tunnels (another international patent) increase the hull lift. Thus, the ride is more comfortable under any sea conditions. The combination of these sophisticated and rigorously tested design choices delivers exceptional performances.

A ZAR hull design is the result of rigorous mathematical calculations, simulations and continuous refinement to ensure safety, comfort and performance. Each prototype is tested and improved upon until it reaches the standards of the project as well as Formenti’s creative philosophy. Tests are carried out in multiple sea, surface and atmospheric conditions. The results help to define the deck’s space and volume. This is carefully calibrated to deliver dynamic and static balance of the boat under any condition and at any speed.

Latest Technology

Once the virtual project is perfectly designed, huge five- point computer numerical control machines (CNCs) give shape to the real boat. In the 2000s Formenti began to integrate 3D design software. This enabled them to further implement more modern technological information. These routers systematically cut, drill, plane and refine giant pieces of resin. The combination of software, concise cutting, and continuous refinement allows maximum precision in scaling models and molds. Through careful polishing, the grace of handwork finishes the final prototype from which molds can be generated.

When the molds are ready, the boatyard commences the next structural stages of fabrication; molding, tubolars, gluing, scuttlebutts and pillows. Under the management of skilled production leadership, the advanced technology behind the design partners with ZAR teams’ craftsmanship. A ZAR is born.

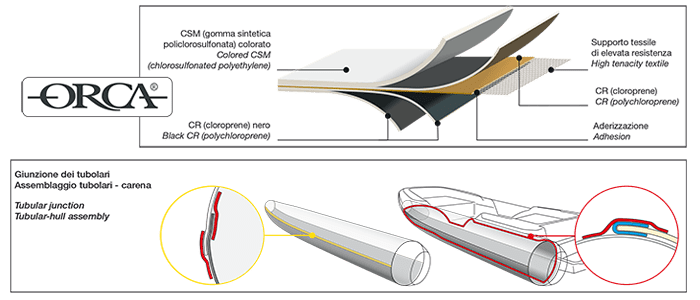

FABRIC

Zar Formenti uses ORCA® products from Pennel Industries for the rubberised parts of ZAR boats. Belgium based, ORCA® has been an established leader in the fabric and materials industry since 1924. ZAR utilises their “High-Tenacity” polyester fabric which is manufactured with CSM (chlorosulfonated polyethylene) and polychloroprene coatings. Such fabric and construction material is used on river expedition rafts, aeronautical vehicles, emergency and quick response rescue vessels and airplane evacuation slides.

The chemical formulas and high tenacity fabric products provide significant abrasion, fire and ultra-violet light resistance. In addition, they are hydro-carbon resistant and perform with a high level of mechanical resistance. Not surprisingly these fabrics are highly recommended for workboats. Despite the durability of the products used in ZAR manufacturing, they can be repaired with kits offered by multiple on-line sources.

These carefully tested and calibrated materials choices ensure the standards of safety and performance demanded by the Formenti designs.

ORCA® offers a wide range of light fast colours.

ROOM ONBOARD

Since its beginnings, ZAR Formenti Inflatables, Rigid Inflatables and Tenders have made onboard quality of life and boat flexibility guiding beacons. With four international patents and a versatile range of hulls to follow, ZAR has demonstrated a pioneering excellence in the industry.

Aft design modifications and the elimination of bow tubolar elements lend to a generous amount of room for seating, stowage and movement. Aft seating usually only consists of a modest bench but on a ZAR, one finds a veritable “lounge” through a redesigning of the stern. Seated, one enjoys modular backrests and cushions. Helm operation on many Zars accommodates seating, standing or partial standing with the polished ergonomics of the controls and cushions. Offsetting some pilot stations allows the option for a wider corridor for easier movement.

One is again made aware of the designers’ concern for safety and comfort by the number of grab handles alongside a generous seating area. Nor does a ZAR boat lack locker space. Each model offers progressively more abundant space for anchor gear, passenger cargo and other accessories. A swim platform(s) accessed by stainless steel ladder(s) enhances the passenger experience as well. In each model, there is a range of accessories and options which enhance passenger experiences and the ideals of functionality and practicality ZAR embraces.

Thank You For Reading

Check out our latest posts below: